With the continuous development of the global fishery industry, fishing boats, as an important tool for modern fishery production, are no longer just traditional fishing vehicles. More and more high-tech and high-performance components are integrated into fishing boats to meet higher production needs and complex marine operating environments. As a crucial component of this, the durability and reliability of the fishing boat transmission have become an important criterion for measuring the overall performance of a fishing boat, and have even gradually become the industry standard.

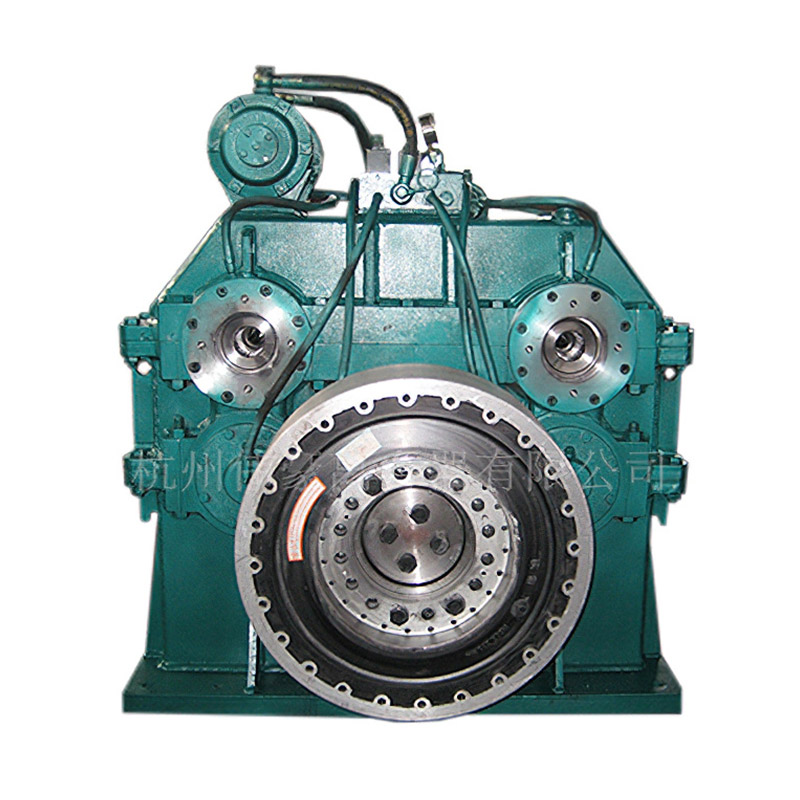

The primary function of the fishing boat gearbox is to efficiently transmit the power of the engine, so that the ship maintains a stable working state under different speeds and loads. Compared with other marine equipment, the working environment of the gearbox of the fishing boat is extremely harsh. Long-term sea navigation, complex marine climate changes and heavy workloads have caused the fishing boat gearbox to bear huge mechanical pressure and high-strength frequency of use. Therefore, durability and reliability are the primary considerations in its design and manufacturing.

First, the durability of the fishing boat gearbox directly affects the long-term operational efficiency of the ship. Offshore operations often require continuous operation of fishing boats and often face harsh climatic conditions. Extreme environments such as storms, waves, and freezing pose great challenges to the ship's mechanical systems. To cope with these harsh conditions, fishing vessel gearbox usually use high-strength materials and optimized internal structure design to ensure that they can still operate stably for a long time in high-load, high-vibration environments. This design allows the fishing boat gearbox to withstand the impact and friction during sea navigation, significantly extending its service life.

Manufacturers of fishing vessel gearbox often introduce advanced engineering technologies when designing, including precise material selection and precise machining processes, which greatly improve the overall durability of the gearbox. In addition to common steel materials, some high-end fishing vessel gearbox also use lightweight and high-strength materials such as aluminum alloys and titanium alloys, which effectively control the weight of the gearbox, and at the same time enhance its corrosion resistance and adapt to more complex marine environments.

Reliability is another key indicator of the gearbox of the fishing boat. As an important part of the fishing boat power system, any gearbox failure may to ship suspension, affect fishery production, and may even cause economic losses. Therefore, the high reliability of the fishing boat gearbox can greatly reduce the risk of ship shutdown due to equipment failure and ensure that the fishing boat can continue to operate efficiently under different operating conditions. To improve reliability, modern fishing vessel gearbox will focus on precision machining and high-standard inspection procedures when designed and manufactured to ensure that each gearbox can operate stably under operating conditions. In addition, the gearbox of the fishing boat also needs to have a certain self-regulation and protection mechanism. Once abnormal situations occur, it can alarm in time through an intelligent monitoring system to avoid more serious failures.

In practical applications, the reliability of the fishing boat gearbox is crucial to reducing operating costs. Traditionally, once a mechanical system on a fishing boat fails, the cost of repairing and replacing is often very high. More importantly, the time required for maintenance may to long-term shutdowns on fishing boats, affecting fishing operations. Therefore, the high technical reliability of the fishing boat gearbox can minimize the probability of failure, ensure that the ship can operate efficiently and continuously, and reduce the cost of maintenance and shutdown for ship owners.

With the development of technology, more and more fishing vessel gearbox have introduced intelligent technology, which provides strong support for improving durability and reliability. Today's fishing vessel gearbox can not only predict faults through real-time monitoring, but also automatically adjust their working status to meet different operating needs. This intelligent technology undoubtedly improves the stability and compressive resistance of the gearbox, and also allows fishing boats to better cope with the ever-changing marine environment during operation.

In addition, the intelligent management of the gearbox of the fishing boat also helps predict and extend the service life of the equipment. With sensors, data analysis and artificial intelligence technology, modern gearboxes can monitor operating status in real time

EN

EN English

English 中文简体

中文简体

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>